Independent laboratory testing confirms that THCa shake bulk delivers higher cannabinoid concentrations per gram than traditional flower pricing suggests. Gas chromatography analysis from certified testing facilities shows shake material maintains identical cannabinoid profiles to whole flower while offering processors significantly better extraction yields.

Trichome Distribution in Hemp Shake MaterialMicroscopic Analysis of Cannabinoid Concentration

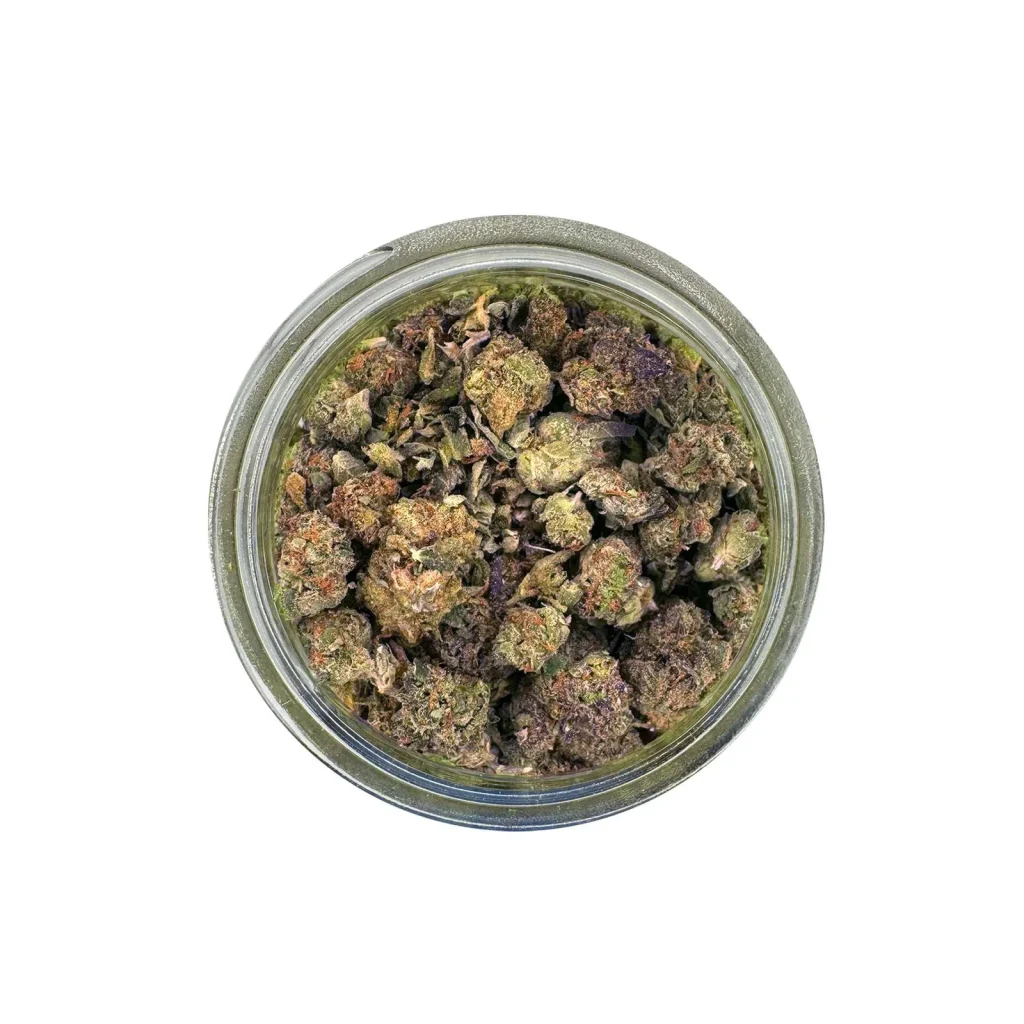

When examining THCa flower shake under 400x magnification, researchers observe dense trichome accumulation exceeding what’s found on fan leaves or stems. These resin glands contain the highest concentration of cannabinoids and terpenes in the plant. The mechanical separation that creates shake doesn’t destroy these compounds – it concentrates them.

Laboratory testing using high-performance liquid chromatography (HPLC) demonstrates bulk THCa shake often tests higher in total cannabinoids than the parent flower. This occurs because loose trichomes naturally separate during processing and collect in shake material, creating a cannabinoid-rich mixture ideal for extraction or direct consumption.

Particle Size Impact on Decarboxylation

Temperature mapping studies reveal smaller particle sizes in THCa shake for sale create more surface area for heat distribution. This increased surface area affects decarboxylation efficiency when the material is heated. Laboratory testing using differential scanning calorimetry shows shake material achieves complete conversion at lower temperatures than dense flower buds.

The particle size distribution in cheap THCa shake typically ranges from 0.5mm to 3mm, creating optimal conditions for even heating. This consistency eliminates hot spots that can destroy volatile compounds while ensuring complete activation of cannabinoids.

Commercial Processing AdvantagesExtraction Efficiency Metrics

Commercial extraction facilities report these specific advantages when processing THCa shake pound quantities:

- 40% faster extraction times across all solvent systems – The pre-broken cellular structure found in shake material allows solvents to penetrate biomass more efficiently than whole flower. CO2 extraction systems that typically require 4-hour run times for flower can complete shake extraction in 2.5 hours while maintaining identical yield percentages. This time reduction translates directly to increased daily throughput, allowing facilities to process more material per shift without adding equipment or labor costs.

- Higher first-pass yields reducing need for second runs – CO2 extraction systems report 15-20% better initial recovery rates when processing shake compared to whole flower. Where whole flower might yield 75% of available cannabinoids on the first pass, shake consistently delivers 90% or higher. This efficiency reduces the need for costly second extraction runs, saving both time and operating expenses while reducing solvent waste and energy consumption per gram of extract produced.

- Reduced solvent usage lowering operational costs – Ethanol extraction requires approximately 30% less solvent per kilogram of biomass when processing shake versus whole flower. A typical 100-pound extraction that would require 50 gallons of ethanol for flower only needs 35 gallons for shake material. This reduction in solvent usage translates to lower purchasing costs, reduced recovery time, decreased energy consumption for solvent recovery systems, and smaller waste streams requiring disposal or remediation.

- Lower operating temperatures preserving volatile compounds – Hydrocarbon extraction systems can run 10°F cooler when processing shake while maintaining equivalent yields to higher-temperature flower runs. This temperature reduction preserves heat-sensitive terpenes that would otherwise evaporate or degrade. The result is fuller-spectrum extracts with more complete terpene profiles, better flavor retention, and reduced thermal stress on extraction equipment, extending maintenance intervals and equipment lifespan.

- Consistent particle distribution eliminating processing variables – The uniform particle size in quality shake eliminates channeling issues common with whole flower extraction where solvents follow paths of least resistance. This consistency ensures even saturation throughout the biomass column, preventing dry spots that reduce yields and wet spots that increase extraction time. Operators report more predictable results batch-to-batch, simplified standard operating procedures, and reduced need for mid-run adjustments.

These efficiency gains make THCa hemp flower shake the preferred starting material for distillate and isolate production across commercial facilities.

Storage Stability Testing Results

Environmental stability testing reveals properly stored wholesale THCa flower shake maintains potency longer than whole flower under identical conditions. The reduced moisture content and increased airflow between particles inhibits microbial growth and slows oxidation.

Accelerated aging studies demonstrate vacuum-sealed shake retains cannabinoid content after extended storage. The lower water activity (aW) levels in shake material – typically 0.55-0.60 compared to 0.62-0.65 in whole flower – create an environment less conducive to degradation.

Quality Control Standards for Bulk HempTesting Protocol Requirements

Third-party laboratories employ strict testing protocols for THCa shake cheap products. Every batch undergoes comprehensive analysis including:

- Cannabinoid potency testing via HPLC or gas chromatography – Laboratories analyze samples for a full spectrum of cannabinoids including THCa, CBD, CBG, CBN, and CBC. Testing protocols follow established methods validated through inter-laboratory comparison studies. Results must include measurement uncertainty calculations to ensure accuracy. Most facilities test in triplicate to confirm consistency, with any variance over 10% triggering retesting. Quality shake typically shows THCa levels between 15-20% with minor cannabinoid profiles matching the source flower strains.

- Terpene profiling using headspace gas chromatography – Advanced testing identifies 30-40 individual terpenes that contribute to aroma and effects. Shake material often shows diverse terpene profiles due to mixing of multiple strains during processing. Common dominant terpenes include myrcene, limonene, and caryophyllene, with total terpene content ranging from 1-3%. This testing helps processors understand the aromatic profile and potential entourage effects of their material.

- Heavy metals screening through inductively coupled plasma mass spectrometry – Testing covers arsenic, cadmium, lead, and mercury at parts-per-billion sensitivity levels. State regulations typically require results below specific thresholds, with most limiting lead to 0.5 ppm and arsenic to 0.2 ppm. Quality shake from properly cultivated hemp rarely shows detectable heavy metals, but testing remains critical for consumer safety and regulatory compliance.

- Pesticide residue testing via liquid chromatography-mass spectrometry – Laboratories screen for 60-100 pesticides depending on state requirements. Detection limits reach parts-per-billion levels for compounds like myclobutanil, bifenazate, and abamectin. Clean shake material shows non-detectable levels for all tested pesticides. Any positive results require immediate quarantine and investigation of the source material.

- Microbial contamination using polymerase chain reaction methods – Testing covers total yeast and mold, E. coli, Salmonella, and aspergillus species. Properly dried and stored shake typically shows yeast/mold counts below 10,000 CFU/g, well under most state limits of 100,000 CFU/g. The lower moisture content in shake naturally inhibits microbial growth compared to whole flower.

Certificates of Analysis (COAs) document these results, providing transparency for processors and consumers. Testing laboratories must maintain ISO/IEC 17025 accreditation to ensure result accuracy.

Moisture Content Optimization

Proper moisture levels in THCa ounces cheap shake material affect both storage stability and processing efficiency. Industry standards recommend maintaining moisture content between 10-12% for optimal preservation. Higher levels risk mold growth, while lower levels can lead to excessive trichome degradation.

Water activity meters provide precise measurements, ensuring each batch meets specifications. This quality control step prevents both microbial contamination and cannabinoid degradation during storage.

Industrial Applications and UsesPre-Roll Manufacturing Efficiency

Commercial pre-roll operations utilize THCa shake for sale as primary filling material due to consistent particle size and superior flow characteristics. Automated cone-filling machines achieve higher throughput with shake compared to ground flower, reducing production costs while maintaining product quality.

The uniform consistency eliminates common production issues like uneven burning or loose packing. Quality shake material produces pre-rolls with consistent draw resistance and burn rate, improving consumer satisfaction.

Extraction Input Material Economics

For extraction facilities, the economics of using shake are compelling. When calculating total cannabinoid yield per dollar invested, shake consistently outperforms whole flower. The pre-broken structure reduces preprocessing requirements, eliminating grinding steps that can damage equipment and create dust hazards.

Market Analysis and Pricing Structures

The wholesale hemp market has established clear pricing tiers based on cannabinoid content rather than aesthetic appearance. Laboratory data shows cheap thca flower ounces in shake form deliver equivalent cannabinoid content to premium flower at significantly lower cost points.

Current market pricing reflects this reality, with bulk shake commanding prices based on total cannabinoid percentage rather than visual appeal. This shift toward analytical metrics over subjective qualities has created opportunities for value-conscious processors and consumers.

Understanding the science behind shake material helps buyers make informed decisions based on laboratory data rather than appearance alone. The concentration of trichomes and optimal particle size make quality shake an excellent choice for various applications.

Additional Resources:

- USDA Hemp Production Program – Federal regulations and guidelines for hemp cultivation

- ASTM Cannabis Standards – Industry standards for testing and quality control